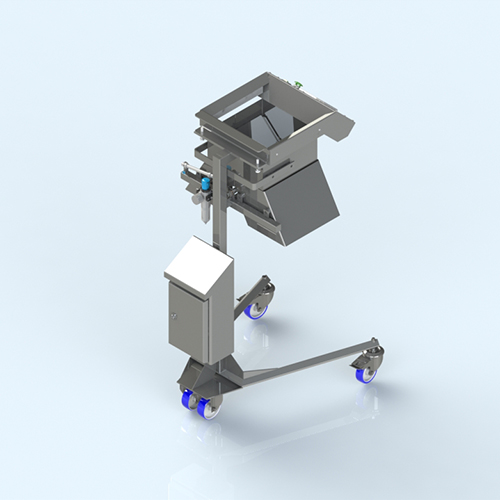

Counting machine

With the Van Rijn counting machine, it is possible to automatically and accurately count products within a production process. This eliminates the possibility of over-packaging, resulting in time and money saved.

Automatic product counting

Van Rijn provides various solutions for filling your product. The purpose of the counting machine is to eliminate the need for manual counting. This reduces a lot of manual work and increases the reliability of the production process.

The machine can count everything between 5 and 200 millimeters, including:

- Sachets

- Trays

- Cosmetics

- Small buckets

- Tablets

- Pills

The sachets can be transported to the counting machine via a conveyor belt, by hand or in some other way. The sachets are counted using infrared technology. When the desired number of sachets is reached, a pneumatic slide opens, allowing the correct number of sachets to drop to the next stage in the production process. This is also indicated by an audible signal.

The counting machine has the following features:

- Adjustable from 1 to 9999 sachets per batch

- Audible signals when the desired number is reached

- Counting range of 5 mm to 200 mm

- Voltage 230 volts-50 Hz

Customized to your needs

The counting machine can be integrated into a production line or purchased as a stand-alone unit. The machine is easy to adjust to the desired number of sachets per batch/box.

Product attributes

- Counting range from 5mm to 200mm

- Much more efficient than manual counting

- As a stand-alone unit or part of a production line

Sales Director

Need advice or do you have a question?

Related products

Van Rijn is a specialist in filling and sealing various types of packaging. Are you curious about our solutions? Then check out our other systems using the links below!

Ideal to quickly transport a large amount of goods

Creates rest and efficiency in the production process

Work on the right height with a solid platform